ZHENGZHOU TOPPU INDUSTRY CO., LTD

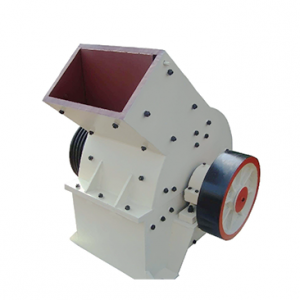

Small mobile sand making machine building demolition site hammer crusher cement block granite sand making machine

Hammer crusher is mainly suitable for the crushing operation of various brittle materials, such as stones, chemical non-flammable and explosive materials, and non-high toughness materials. Large crushing ratio and high production efficiency are the advantages of the hammer crusher. The hammer crusher can be used for dry and wet crushing. The hammer crusher is used to crush various medium-hardness and abrasive materials. The strength of the compressive materials is not Over 100MPa, the water content is less than 15%. Mainly used for coal, salt, chalk, gypsum, bricks, limestone, etc., it can also be used to crush materials with fiber structure and elasticity. The hammer crusher can be used not only for stone production lines, sand production lines, but also for beneficiation production lines. Cone crusher. Hammer crushers can be divided into horizontal crushing and vertical crushing. They can be customized and modified for different use requirements. They have a wide range of applications and are used in various industries such as mineral processing, construction, chemical industry, and waste recycling.

Features

Working principle

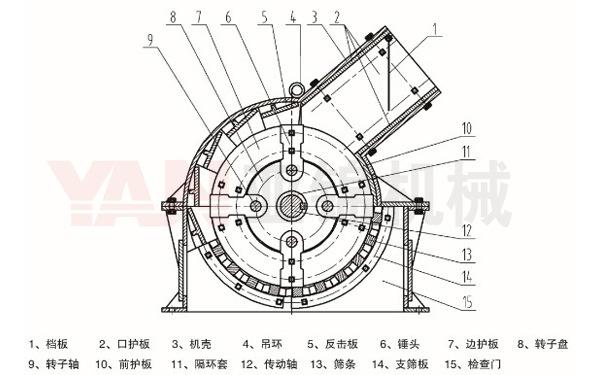

When the hammer crusher is working, the motor drives the rotor. The rotor rotates at a high speed in the crusher chamber. The material enters the chamber from the upper feeding port. The material enters the strong chamber and receives the impact of the high-speed moving rotor, breaking, shearing, and grinding. It is crushed under multiple gravity. The lower part of the hammer crusher is equipped with a sieve plate. After being crushed, the material falls into the sieve plate hole and is discharged out of the machine through the sieve hole. The size of the sieve hole can be made according to the requirements of the particle size of the material. , The material smaller than the sieve hole is discharged out of the machine body, and the material larger than the sieve hole continues to be hit and ground by the hammer until it is discharged out of the machine after the hole is smaller than the sieve hole.

Features

1. The working hammer is cast with a new technology, which is wear-resistant and impact-resistant;

2. According to customer requirements, the required granularity can be adjusted;

3. The hammer breaks the machine body structure to seal, which solves the dust pollution and machine body dust leakage problems in the crushing workshop;

4. The overall design has the advantages of beautiful appearance, compact structure, few wearing parts, and convenient maintenance. It is an upgraded product;

Technical Parameters

|

Type |

Input size(mm) | Output size(mm) | Capacity(m³/h) | Power(kW) | Weight(t) | Overall dimension(mm) |

| PC200x300 | ≤200 | 0-25 | 2-5 | 5.5 | 0.6 | 700x540x660 |

| PC400x300 | ≤300 | 0-35 | 5-10 | 11 | 0.8 | 900x670x860 |

| PC500x350 | ≤320 | 0-35 | 8-15 | 18.5 | 1.2 | 1000x770x900 |

| PC600x400 | ≤400 | 0-40 | 10-22 | 22 | 2.26 | 1200x1050x1200 |

| PC600x600 | ≤400 | 0-40 | 15-30 | 30 | 2.6 | 1300x1000x1250 |

| PC800x600 | ≤500 | 0-40 | 18-40 | 55 | 3.1 | 1310x1180x1310 |

| PC800x800 | ≤600 | 0-40 | 25-45 | 55 | 3.5 | 1440x1740x1410 |

| PC1000x800 | ≤650 | 0-40 | 25-50 | 75 | 5.9 | 1600x1390x1575 |

| PC1000x1000 | ≤700 | 0-40 | 30-55 | 132 | 8 | 1800x1590x1775 |

| PC1250x1250 | ≤800 | 0-40 | 35-65 | 180 | 14 | 2060x1600x1890 |

| PC1400x1400 | ≤1000 | 0-40 | 50-100 | 280 | 32 | 2365x1870x2220 |

| PC1600x1600 | ≤1200 | 0-40 | 100-150 | 480 | 37.5 | 3050x2850x2800 |